Westinghouse AP1000™ Nuclear Plant Program

Engineering and design services for Westinghouse AP1000™ pressurized water reactor

Westinghouse Electric Company

|

USA and China

|

2010-2012

Site specific design enhancements for future AP1000™ PWR units

Services for the first U.S. units and Chinese units

designs reviewed for safety, operability and maintainability

Challenges

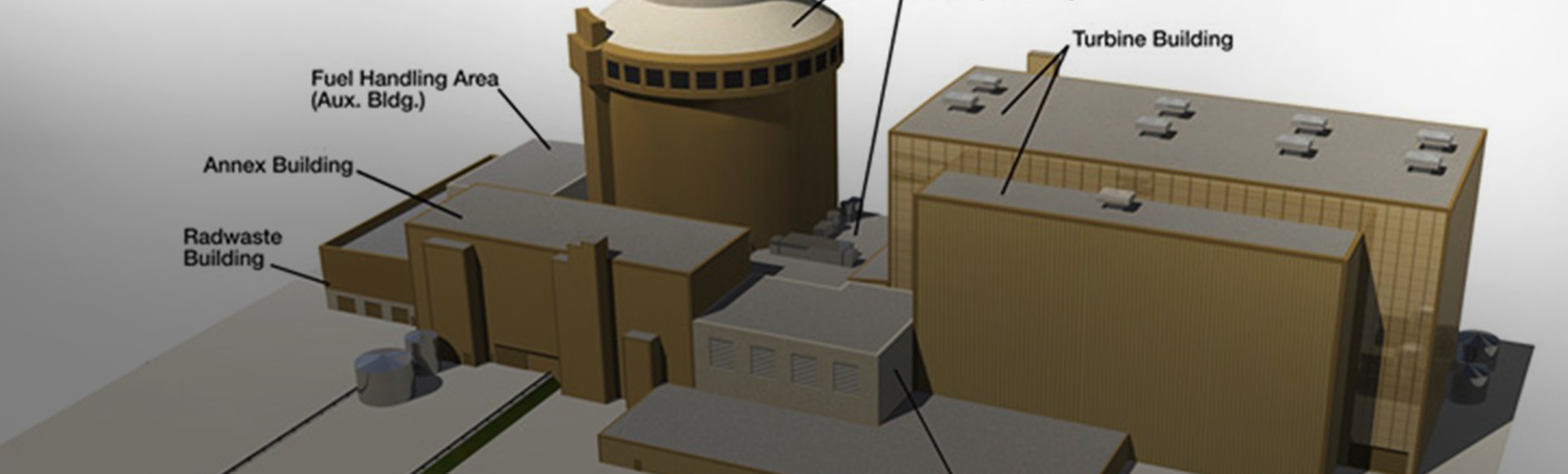

The Westinghouse AP1000™ pressurized water reactor is an advanced 1100-MWe nuclear power plant. It is a modular design that uses 50 percent fewer valves, 35 percent fewer safety grade pumps, and 80 percent less piping than previous nuclear plants. It also features a passive safety design. Six utilities have chosen the AP1000™ PWR for use in seven combined construction and operating license (COL) applications to the U.S. Nuclear Regulatory Commission (NRC) for a total of 14 AP1000™ units, including six for which engineering, procurement and construction contracts have been signed. Additionally, four units are under construction at two sites in China, with the first unit to come on line in 2013.

Solutions

- Hatch was retained to provide engineering and design services to assist in the development of construction drawings for the containment and auxiliary buildings.

- Supported Westinghouse’s structural, piping, layout, mechanical modules, and structural modules groups for a 17-month period which began in January 2010.

- Hatch also provided a team of engineers to perform finite element analyses of key structural floor and modules.

Highlights

- Hatch’s services included 3D PDS modeling and 2D CAD services.

- Designs reviewed for safety, operability and maintainability, even though Hatch has no direct site involvement.

- Staff assigned in Westinghouse’s office and Hatch’s Pittsburgh office.