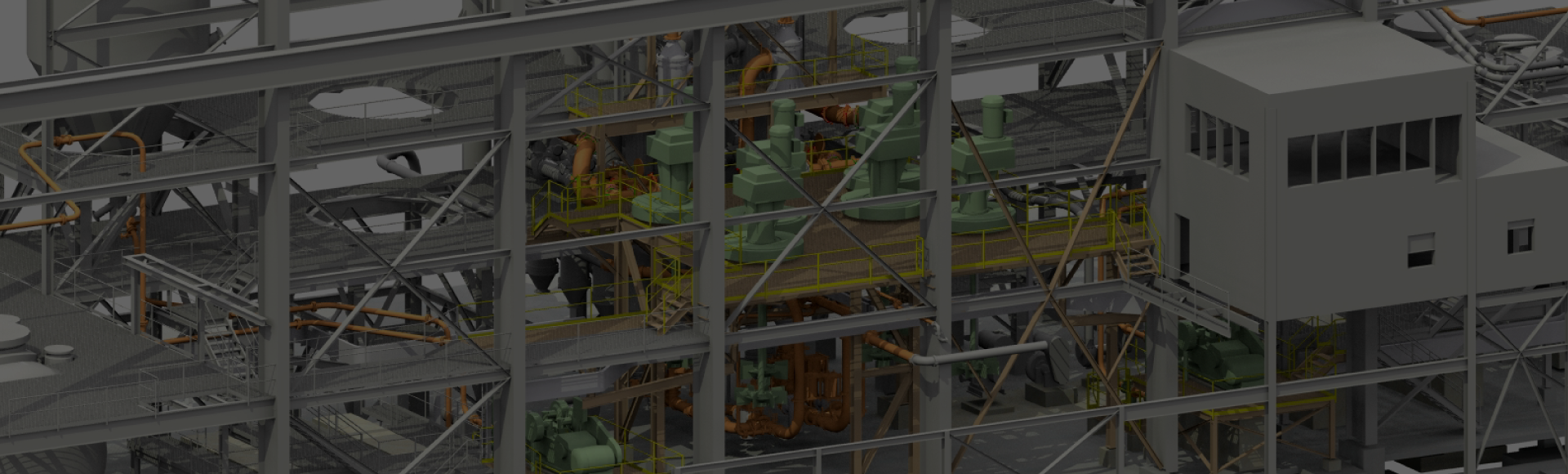

Twin Creeks Autoclave Tonnage Improvement

Pre-feasibility, feasibility, execution

Newmont Mining Corporation

|

Nevada, USA

|

Dec 2008 – Jan 2010

Debottlenecking study increased plant throughput production greater than 20%.

Brownfield execution coordinated with planned annual shutdowns.

Project completed on schedule and under budget.

Challenges

- The project required a study to evaluate options for improving the ore tonnage through the Sage Mill autoclave circuits at the Twin Creeks facility in Nevada USA.

- Original goal of the study was to increase the total tonnage of ore to each autoclave by a minimum of 20 stph, representing a ~9% increase over existing average throughput.

Solutions

- Provided engineering services to debottleneck the existing circuit, identifying all piping and equipment requiring either upgrade or replacement to meet the targeted throughput.

- Study work included calibration of a mass and energy balance using available plant operating data, and computational fluid dynamic (CFD) modeling to evaluate and optimize autoclave agitator performance and oxygen mass transfer.

- Upgrades included installation of refurbished positive displacement feed pumps to increase overall throughput, modifications to autoclave agitator impeller and baffling design to improve mass transfer, and installation of new titanium slurry coolers to increase slurry cooling capacity downstream.

Highlights

- Execution of the project was completed during normal operation of existing plant, with minimal down time for tie-ins.

- Project was completed on schedule and under budget.

- Since implementation, throughput capacity has increased significantly well beyond original project targets, while maintaining target sulfide oxidation levels and gold recovery.

How we can help you

If you have a problem that needs to be solved, please get in touch.