Habshan Sulfur Granulation

Engineering one of the largest sulphur-granulation installations in the world

GASCO

|

United Arab Emirates

|

2011–2013

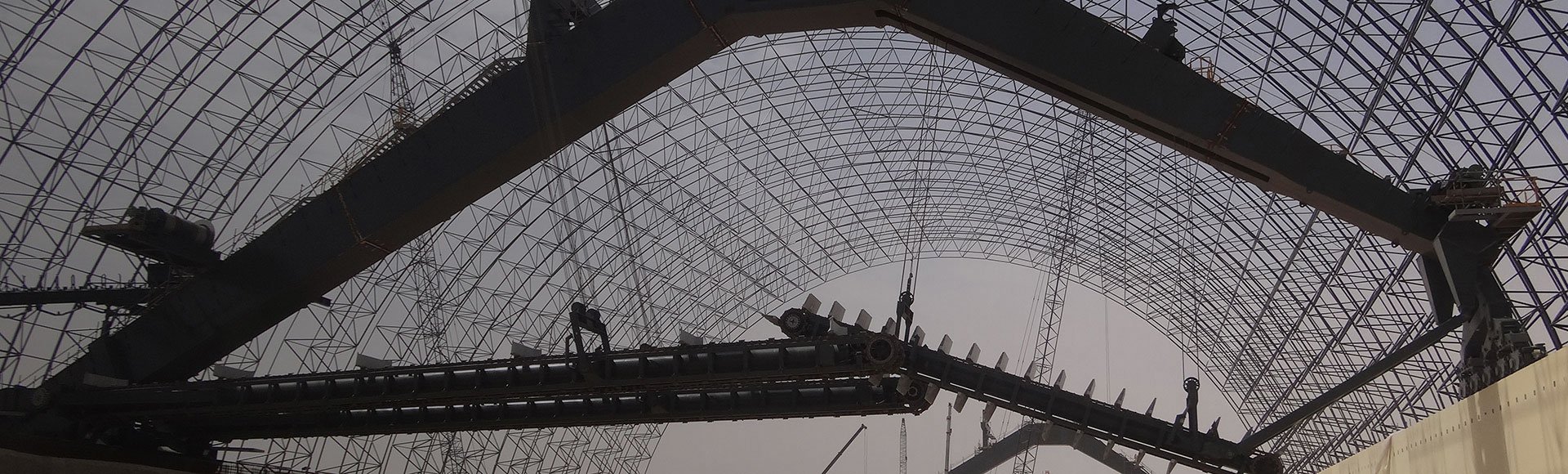

180,00-tonne covered-storage stockpile.

11,000-tonne-per-day sulfur-granulation plant.

75-km pipeline.

Challenges

- GASCO set out to build the largest integrated gas-to-liquids refinery in the world.

- Liquid sulfur would arrive from existing Habshan gas plants via skin-effect electrical tracing (SEET) pipelines.

- The liquid sulfur would then be granulated at the facility, stockpiled, and ultimately transported via rail to a new sulfur handling terminal at Ruwais.

- The right measurements were required to effectively handle the friable sulfur granules and mitigate concerns surrounding fire hazards.

Solutions

- Provided detailed engineering and procurement support services for the upstream liquid-sulfur delivery pipeline and the downstream bulk-material-handling facility.

- Included two stacker-reclaimers in the bulk-material-handling system that were integrated within a conveyor network that then connected to a railcar-loading facility.

Highlights

- The materials-handling system used many automation strategies to ensure the designed "hot-spare" redundancy provisions were effective.

- Developed a custom stockpile-management philosophy to eliminate shelf-life issues for sulfur kept in storage.

- With 12 granulators and an extensive network of sulfur pipelines, this is one of the largest sulfur granulation installations in the world.

Project numbers

7 conveyors1,000-tonne surge bin

4,000-tonne per hour rail-car-loadout facility

5 wet-dust-collection-scrubber towers