Challenges

In a highly competitive global commodities marketplace, the demand for increased productivity is straining traditional production processes and the human workforce.

Safety standards are increasing in the mining and metals industry, but so too are the demands on the workforce, subjecting human operators to undesirable risks. At the same time, these workers are skilled and provide judgement that is difficult to replicate by a machine, making the processes difficult to automate.

Industrial robots have been developed for over six decades to automate repetitive human tasks reliably in manufacturing industries and are now cost-effective commodity equipment. Many human tasks could benefit from automation, but it still takes a lot of expertise to engineer a system that can survive the harshness of the mining and metals environment. The robot alone is just one piece of the puzzle in a fully integrated solution!

Capabilities

Design for Harsh Environments

Extreme temperatures, dust, corrosion, and impact loads are all factors commonly found in the mining and metals industry that are detrimental to machine reliability. We have more than 60 years of experience designing against these unique challenges and extend this capability to industrial robotics.

When equipped with foundry grade trims, the industrial robot is already a rugged machine. In order to survive the most extreme environments, we will engineer additional protection so that it can be a highly reliability piece of equipment, on-par with heavy machinery.

Intelligent Sensors for Localization

The robot is only “a one-armed blind man” and most applications in mining and metals cannot be well-constrained or fixtured. Therefore, sensors are required to detect and localize components that need manipulating. A variety of sensor technologies have been developed to provide reliable, cost-effective operation in complex environments, each offering their own benefits. We select the most appropriate sensing technology to achieve your required outcome and integrate it into your system with custom software when the “out-of-the-box” software solutions won’t suffice. We have extensive experience integrating 2D machine vision sensors, 3D structured light sensors, and 3D laser triangulation sensors—amongst others—into robotic systems.

On-the-Fly

In addition to being unfixtured, many applications in the mining and metals industry that could benefit from automation involve moving parts. Stopping the process to automate may have negative effects and is just another reason why humans are so good at performing these tasks. We have developed custom robotic applications that use several sensors to synchronize the robot’s motions with a moving part or process to perform tasks while “on-the-fly”.

Force and Compliance Control

Thanks to our compliant appendages and sense of touch, humans are great at tasks requiring high dexterity. Although robots were primarily designed as position-control devices, the addition of a force transducer and integrating technology allows them to be used in tasks where constant force is required or where forces need to be limited. Soft-axis capabilities allow them to behave with a compliant touch. We have developed applications with these features and can provide it as an option where necessary.

Telerobotics

Many applications can never be fully automated because some conditions require a trained operator’s skill and judgment. However, these applications may also expose the worker to hygiene or ergonomic issues or place them in a direct line of fire.

Telerobotics refers to the practice of remotely controlling a robot by a human operator. Compared to a human, a robot can lift heavier loads, reach farther places, have a steadier hand, tolerate higher temperatures, and withstand a toxic atmosphere. With a telerobotic system, these benefits are paired with the worker’s skill and judgement while moving them out of harm’s way.

Our proprietary technology allows real-time motion control of a standard industrial robots and can provide haptic feedback to the operator to retain the same natural and intuitive interface. This technology can be applied to a wide variety of applications and enable robotic automation where it may otherwise seem impossible.

System Development & Deployment

With roots in engineering consulting, we have considerable experience with innovation and concept studies that include problem definition, and options generation and selection.

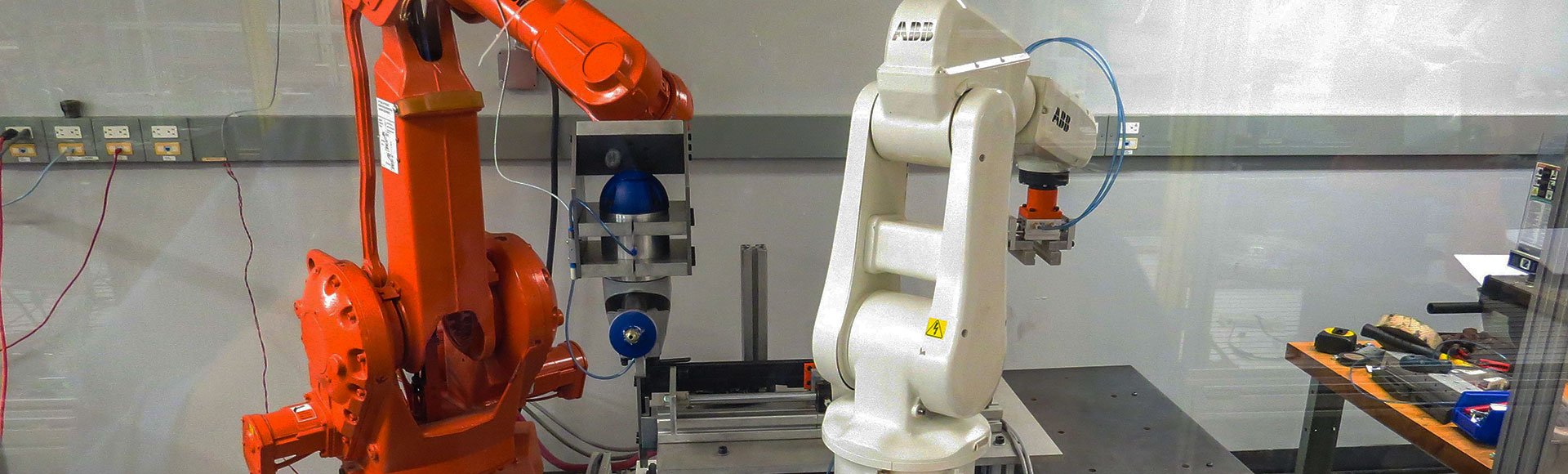

Given the flexibility of the robotic options, we’re making use of our partnerships with local colleges and ABB to “get physical fast” and provide cost-effective, small-scale proof-of-concepts for de-risking options.

Finally, our multidisciplinary, integrated Hatch teams use our specialized skills and groups—such as custom machine design, controls technology, digital transformation specialists, and process subject matter experts—to create custom solutions that solve your toughest challenges. Our Engineered Equipment group offers the complete system on a design and supply basis and provides installation, commissioning, and start-up support, as well as after-sales service.