Reducing emissions for a changing climate with stricter government oversight

With greater awareness of the impacts of climate change and air-borne pollutants, governments are continuously enacting stricter emissions regulations. This is a particular challenge for industrial facilities with aging infrastructure, who seek to not only weather, but innovate within this changing regulatory landscape while minimizing outages and retrofits. As the custodian of vast knowledge in this area, how can we help our clients to adapt and grow while pursuing a better and greener world?

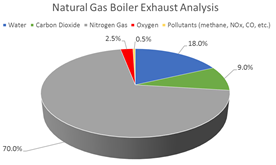

Understanding the formation and the impact of various emissions is important in effectively treating them.

Three common combustion pollutants are particularly harmful to the environment: unburnt hydrocarbons, particulate matter, and nitrogen oxides (NOx).

Figure 1: The composition of typical boiler exhaust when fueled by natural gas

Unburnt hydrocarbons, most significantly in the form of methane, are released from incomplete combustion and have about 30 times the global warming impact as compared to carbon dioxide (CO2). Properly maintained stationary combustion equipment (i.e. power plants, industrial boilers, gas turbines, etc.) typically do not emit significant amounts of methane.

Particulate matter, primarily soot and ash, garners more attention for its health impacts and visibility, but is also a significant contributor to global warming. Ash is non-combustible matter contained in fuels while soot is very fine particulates that form from gas-phase organic reactions. They are mainly emitted from solid and liquid fuels, including vehicle diesel and gasoline engines. Significant amounts settle on ice caps around the earth’s poles, absorbing heat from the sun as a black-body and accelerating glacial melting.

Nitrogen oxides, or NOx, are naturally formed from the air during combustion. However, they are also a key component of smog and have up to 300 times the impact on global warming than CO2. NOx is primarily formed from thermal reactions as nitrogen in the air reacts within high temperature regions adjacent to the flame and from fuel-bound nitrogen, often found in solid fuels.

Given their ubiquity across combustion applications and fuel types, NOx is currently facing the most regulatory scrutiny and emitters across the board are experiencing increasing pressure to reduce their NOx emissions.

This article discusses three common NOx control technologies, but there are many other solutions available, including novel technologies entering the market. It is also important to remember that there is no “one-size-fits-all solution” because every facility faces its own unique challenges and constraints.

A site-specific study is required to select the optimal NOx control technology. A plant’s operating profile, equipment, end-product, regulatory compliance, remaining life, availability of utilities, and efficiency all impact the technology selection. Selecting the right technology can offer significant economic benefits over the long-term operations of a facility.

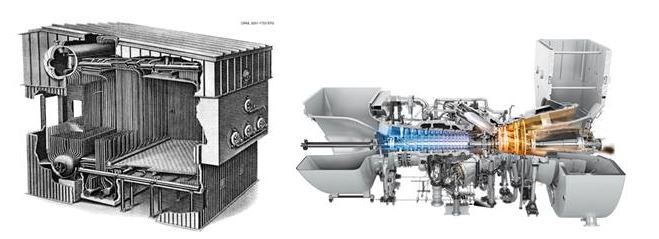

Source: Oland, C.B., Oak Ridge National Laboratory, Guide to low-emission boiler and combustion equipment selection, ORNL/TM-2002/19, 2002, https://compressortech2.com/siemens-secures-fpso-compression-train-order/

Figure 2: Cross-sectional view of the most common power combustion systems - a watertube boiler and industrial gas turbine

(1.) Low NOx burners

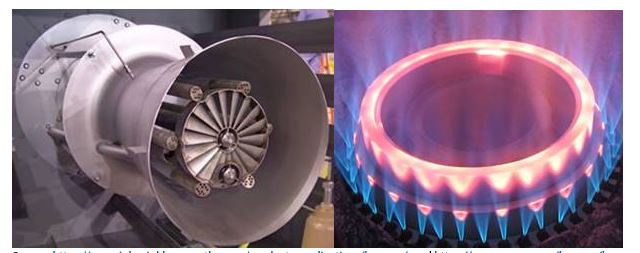

Low NOx burners (LNBs) have been standard equipment in boilers and gas turbines over the past few decades and can be used with any fuel. LNBs precisely control combustion dynamics, chemistry, and flame shape to reduce NOx formed from high temperature regions near the flame and the fuel itself. One common control strategy for LNBs is to stage the fuel and/or air injection to enlarge the flame and reduce combustion intensity and temperatures. Staging the fuel can also form pockets of rich (excess fuel) combustion which is particularly effective to control NOx from fuel-bound nitrogen. Furthermore, precise combustion control means that some low NOx burners can use less excess air, helping to improve overall efficiency.

Source: https://www.johnzinkhamworthy.com/products-applications/burners/ and https://www.zeeco.com/burners/burners-process-glsf-fj-combo.php

Figure 3: Natural gas low NOx burner designs for boiler systems, produced from two major manufacturers

Low NOx burners reduce NOx by up to about 60 percent (compared to an uncontrolled combustion) or up to a 90percent reduction when combined with flue gas recirculation in boiler systems. Low NOx burners are generally sufficient to meet NOx regulations in many jurisdictions when burning natural gas (no fuel-bound nitrogen) with less than 50 ppm readily attainable. In specially engineered applications, under 10 ppm, NOx is possible.

Modifications may be required to retrofit LNBs in an existing boiler, but they are often a very cost-effective option and quicker to implement. Additionally, the burners typically have a negligible impact on other emissions and the efficiency.

(2.) Flue gas recirculation

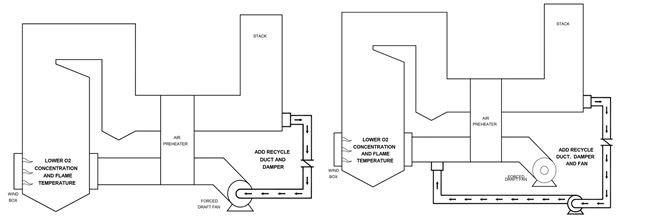

Flue Gas Recirculation (FGR) is another widely used NOx control technology in boilers. FGR reintroduces around 10-20 percent of the flue gas (by mass) from the stack back into the combustion chamber and is effective for use with most fuels and combustion technologies. FGR reduces combustion temperatures by acting as a heat sink and forcing the flame to expand by displacing oxygen from the flame region. NOx formation will then decrease because reactant oxygen concentrations are reduced and its formation is exponentially linked to temperature.

Source: Bell, R.D. & Buckingham, F.P., An overview of technologies for reduction of oxides of nitrogen from combustion devices.

Figure 4: FGR configurations for boiler systems (induced on the left and forced on the right)

FGR is often used in conjunction with other control mechanisms, such as low NOx burners. On their own, FGR systems can reduce NOx by over 50 percent (compared to an uncontrolled combustion) and further reductions can be realized when combined with LNBs. Carbon monoxide and unburnt hydrocarbon emissions will increase slightly with FGR and there will also be a decrease in boiler efficiency, often less than 1 percent. An advantage of FGR is that the amount can be increased for additional NOx reduction should future regulations become more stringent, but the effects on efficiency will be proportional.

FGR installations can have an induced or forced configuration. Induced means that the flue gas is pulled into the windbox using the existing boiler FD fan while a forced configuration has a smaller, separate fan to inject or sparge the high temperature flue gas into the windbox. In either case, the flue gas and fresh combustion air must be thoroughly mixed before entering the burners. Forced installations can be more cost effective as a retrofit, if the existing FD fan can handle the increased back-pressure from the windbox. However, induced configurations are preferable from the perspective of maintenance, gas mixing, and total power draw so greenfield projects should generally be of an induced-type.

A FGR retrofit can impact a boiler in several ways. Steam and tube temperatures will tend to increase, potentially compromising the integrity of older systems, and flame stability in existing burners can be negatively affected, especially if flue gas and fresh air are not thoroughly mixed entering the burners. Existing systems therefore need to be properly studied for suitability for FGR retrofit.

(3.) Selective catalytic reduction

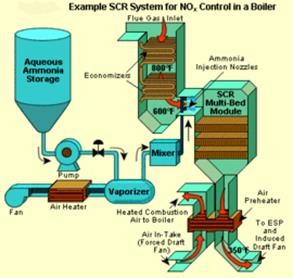

Selective catalytic reduction (SCR) is a post-combustion NOx control technology which will work with any fuel or combustion system. SCRs are catalyst-based systems where urea or ammonia is injected into the flue gas, ahead of the catalyst, forming water and nitrogen gas downstream.

Source: https://www.power-technology.com/projects/nacogdocheswoodfired/attachment/nacogdocheswoodfired3/

Figure 5: Diagram of an SCR system used for a boiler

SCRs are very effective and can reduce NOx emissions by more than 95percent, however SCRs are expensive with capital costs potentially an order of magnitude greater than LNBs or FGR. SCRs also have high operating costs because in addition to purchasing the reacting agents, the catalyst needs to be replaced every 3 to 5 years. The parasitic load of the system will also be higher due to the pressure drop across the catalyst and from operating the ammonia/urea injection grid. Finally, when using less expensive gaseous reagents, such as ammonia, additional safety precautions must be implemented with proper monitoring as the compounds are highly toxic.

The main advantage of SCRs, besides their reduction efficiency, is that they have no negative effect on other combustion emissions or boiler efficiency when the additional pressure drop is offset, if necessary. SCRs were commonly used with coal-fired plants since they effectively reduced the high levels of NOx and the systems could handle the high particulate loads. SCRs are generally not required for cleaner fuels like natural gas.

Conclusions

This publication is intended as a preliminary technology guide to advise readers on common control technologies, along with their benefits and detractions, but with many more options available and novel systems frequently emerging, it is important to do site-specific assessments to determine the best technology for the project. Many factors impact technology selection and must be duly considered including fuel-type, balance of plant equipment, future emission trends/regulatory compliance, capital and operating costs and maintenance requirements. With proper expertise, NOx regulatory compliance can almost always be achieved to the customer’s satisfaction.

Please note, this article is meant as a general guide with reductions based on typical installations from publicly available resources. Every site is unique and therefore results may not be representative.